Warehouse labels are key to making any warehouse run smoothly. Knowing the different types of warehouse labels helps you set up a reliable system to track items, improve inventory control, and speed up restocking and shipping.

Get everything you need to know as we cover the main types of warehouse labels, what each type does best, and why they’re worth using in a busy warehouse environment. We’ll also touch on solutions that make labeling easy and effective, like reusable options and ways to deal with hard-to-remove labels.

Why Warehouse Labels Matter

Using the right warehouse labels can help organize stock, locate items faster, and reduce mistakes in shipping and inventory management. For warehouses with frequently changing inventory, having a quick way to update or move labels is essential.

The Most Popular Labels

Let’s take a look at the most popular types of labels that warehouses rely on.

1. Rack Labels

Rack labels are the main type of label you’ll find on shelving units in a warehouse. A rack label is usually applied directly to the racking and includes barcodes, numbers, or both to help workers quickly identify what’s on the shelf. Rack labels make it easy to track where items are located in real time, saving time and avoiding confusion.

If your warehouse has shelves that need frequent label changes, Electronic Imaging Materials’s Base-N-Switch™ system is a valuable tool. A cost-effective alternative to magnets, it’s designed to hold labels that can be easily placed and removed as inventory changes, without damaging the racks. This reusable label solution makes updates quick and effortless, helping warehouses keep up with constant changes. We even have a blockout version to cover up your old rack labels.

2. Pallet Labels

Pallet labels are used to identify items stacked on top. They’re particularly helpful for large warehouses that rely on stacked inventory and need to keep track of each pallet’s content and location. Pallet labels are usually printed with barcodes and other key details, making it easier to identify and scan entire pallets during inventory checks or shipment.

Since pallets move frequently, their labels need to withstand rough handling. Durable labels that resist scuffing or tearing are ideal. For situations where pallets are frequently reused, removable labels like EIM’s Base-N-Switch™ are perfect. These reusable labels are easy to replace when a pallet’s content changes.

3. Bin and Crate Labels

Bins and crates hold smaller items or group similar items together, making them easy to find and transport. Bin and crate labels are typically smaller, but they still need to be easy to read and durable since these containers may move around the warehouse often. Using color-coded or barcoded labels for bins and crates can help quickly identify where each type of product is stored.

Removable options like Everpeel® are ideal for bins and crates as well. Everpeel® labels allow for easy removal without damaging the container, so you can reuse bins and crates for different products as inventory changes.

4. Totem Labels

Totem labels are often used to show which shelf a particular item is on. These labels are stacked vertically on the side of a shelving unit, displaying information for each shelf level. Totem labels provide a visual cue to help workers easily find the right shelf, making item retrieval faster and reducing mistakes.

Totem labels work well in warehouses with high shelves and multiple levels of stock. They’re typically color-coded or numbered, making it easy to scan a row of shelves at a glance to find the right level. Using durable materials for totem labels can prevent wear and tear, ensuring they remain readable over time.

Tired of time-consuming and confusing inventory management? Learn more about how totem labels simplify the process.

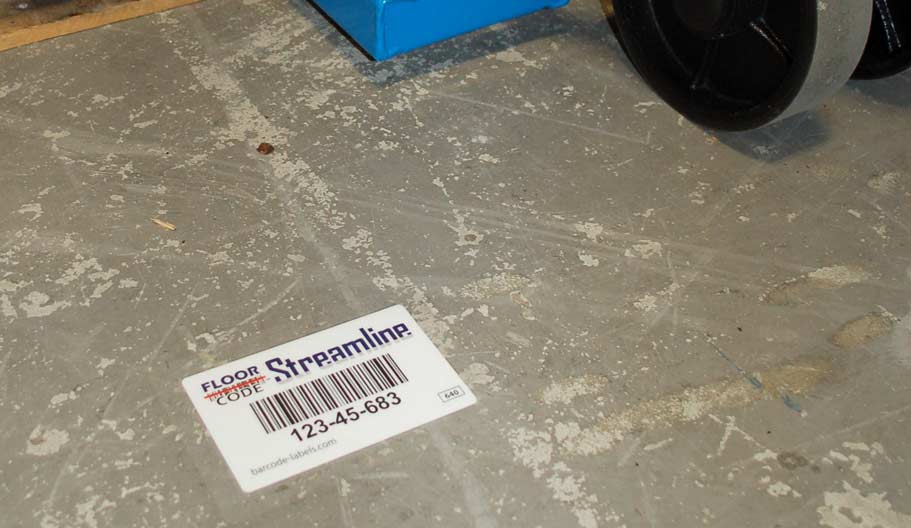

5. Floor Labels

Floor labels are placed on the ground to mark specific areas within the warehouse, like loading zones, pallet storage spaces, or special handling areas. They provide a quick way to show workers where items should go or where safety protocols need to be followed.

Floor labels are typically made of highly durable, slip-resistant materials, as they’re exposed to a lot of foot and equipment traffic. They need to be strong enough to withstand heavy machinery like forklifts. Warehouses that rely on floor markings to keep areas organized and safe can benefit from using high-quality, industrial-grade floor labels that won’t easily peel or fade.

6. Hanging Placards

It can be challenging to label hard-to-reach areas effectively in warehouses with high ceilings. Hanging placards are a great solution for this, as they suspend from the ceiling and hold retro-reflective labels that can be scanned from a distance. This allows workers to scan items or locations without needing to move or get close, saving time and keeping operations efficient.

Hanging placards work best in tall, open areas where scanning from afar is necessary. Durable materials help these labels stay readable and functional over long periods.

7. Reusable Labels: Everpeel®

For warehouses where items or containers are constantly changing, reusable labels offer flexibility and reduce waste. Everpeel® labels are a unique type of label that can be removed and reapplied without losing adhesion or damaging the surface they’re placed on. They’re a budget-friendly alternative to magnets, allowing for quick label updates and seamless changes.

These labels are perfect for reusable containers, bins, and racks, where traditional adhesive labels need frequent replacement. Everpeel’s design keeps labels intact and reusable, supporting warehouse efficiency without the need to invest in costly alternatives.

How to Choose the Right Labels for Your Warehouse

Selecting the correct type of label depends on your warehouse’s layout, storage needs, and how frequently items are moved or replaced. For example:

- Rack labels and pallet labels are key for keeping track of large amounts of stock.

- Bin and crate labels are best for organizing smaller items that are often grouped together.

- Totem labels are ideal for marking shelves by level, making it easy to find products without needing to climb or reach.

- Floor labels are excellent for designating safe zones, specific areas for equipment, or pallet loading zones.

- Hanging placards work well in warehouses with high ceilings where distant scanning is necessary.

- Everpeel® labels offer a flexible, reusable option for warehouses that frequently update their inventory.

Using a combination of these warehouse labels can make it easier to stay organized, locate stock efficiently, and prevent confusion during inventory updates.

Why High-Quality Labels Make a Difference

Reliable, high-quality labels are critical in every warehouse environment. Choosing durable options prevents the need for frequent replacements, which can slow down workflows. Labels like EIM’s Everpeel® and Base-N-Switch™ systems offer reusable, damage-free options that simplify the process of labeling changing inventory.

How Electronic Imaging Materials Can Help

When it comes to finding the best labeling solutions, Electronic Imaging Materials (EIM) has the experience and technology to provide the ideal labels for any warehouse. From high-durability options to reusable labels like Everpeel®, EIM designs labels that meet the needs of busy warehouses with high standards. EIM’s Base-N-Switch™ system even provides an easy way to replace labels on racks, helping to streamline updates without damaging surfaces. By choosing EIM, you gain access to custom and high-quality solutions built to perform in demanding conditions.

If you’re interested in seeing how EIM’s labels can improve your warehouse operations, we invite you to request a sample today. Whether you’re looking for rack labels, pallet labels, or custom solutions for unique labeling needs, EIM’s products can help keep your warehouse organized and efficient.

Knowing the different types of warehouse labels is essential for keeping your warehouse running smoothly. With the right labeling tools, managing inventory and staying organized becomes easier, leading to fewer errors and faster workflows. Reach out to EIM to explore the best options for your warehouse setup and discover how the right labels can make a difference.

Effortlessly Organize Your Warehouse With Durable Labels Built to Last

Upgrade your warehouse labeling with EIM’s high-durability, custom solutions! Discover how our labels can optimize your workflow and keep operations running smoothly—contact us for a free sample today.