Vinyl labels have long been a mainstay for the printing industry because of their excellent tear, chemical, and moisture resistance. On top of that, they are highly conformable, cost-effective, and are perfect for outdoor applications.

But they’ve been getting a bad rap lately. Environmental concerns involving the European Union’s RoHS and REACH Directives have put vinyl, particularly PVC, under the microscope. Most vinyl products contain phthalate plasticizers, a chemical compound that dramatically improves flexibility and cold temperature performance. Vinyl also requires heat stabilizers that could contain derivatives of heavy metals such as lead or cadmium, not to mention flame retardants, smoke suppressors, and other additives during the manufacturing process.

Will vinyl labels soon become extinct?

The demands of RoHS and REACH, as well as the changes in printing technologies, have led to the extensive development of PVC label alternatives, such as polypropylene, polyethylene, and other polyolefins. While these choices are often powerful alternatives, they each come with their own limitations. For instance, polypropylene is not suitable for long-term outdoor exposure.

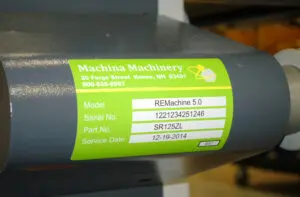

Vinyl labels will continue to sell, however. They’re a top choice for bumper stickers, decals, and warning labels because they are cost effective. Their conformability allows for application on a wide variety of surfaces including tightly curved areas. While they tend to tear a bit more easily than some other plastics and they are not quite as chemical resistant, simply adding a protective over laminate is an easy remedy. They are perfect for GHS Drum labels. Thanks to special topcoats, you can achieve high resolution printing with thermal transfer, inkjet, and laser printers. Looking for a more environmentally friendly option? Check out our green alternative to vinyl.

We stock a variety of vinyl label materials for many applications:

| Vinyl Material | Description |

| 1380 White |

This flexible material packs a strong adhesive that bonds to tough surfaces and includes a 5-year outdoor life. A glossy thermal transfer printable material, it has seen renewed popularity with recent changes in GHS labeling. It bonds well to challenging surfaces such as LSE & HSE plastics, painted metal, powder-coated paint, polycarbonate and fiberglass. |

| 657 White |

This special thermal transfer vinyl comes with the same strong adhesive as 1380, but thanks to it semi-rigid construction, it can be easily repositioned before becoming permanent. One customer loves it for labeling fiberglass propane tanks, complete with full-color logos and warnings. This too, comes with a 5-year outdoor service life. |

| 647 Frosty Clear |

A real crowd pleaser, this conformable clear thermal transfer vinyl has a translucent finish that allows colors to shine through from the surface beneath. It comes with the same adhesive as 1380 and 657 white vinyls. Perfect for cable labels, product ID, safety & warning labels. 2-year outdoor life. |