As we celebrate our 25th Anniversary this year, we thought we would share a “Brief History of our Company” based on the recollections of our founder, Paul Henkel.

In 1987, Paul and his wife Sue invested most of their savings and started working out of a garage, producing labels on a single label-cutting-and-printing machine. In the first few months, there were just the two of them working…they would make sales phone calls and take orders during the day and then manufacture labels late into the night.

In 1987, Paul and his wife Sue invested most of their savings and started working out of a garage, producing labels on a single label-cutting-and-printing machine. In the first few months, there were just the two of them working…they would make sales phone calls and take orders during the day and then manufacture labels late into the night.

Paul recalls that there were pitfalls. There was one disastrous order, for instance, that he completed during a nighttime shift. [In fact, he still keeps a couple of rolls as a stern reminder.] Somehow, a small label got loose during the machine set-up and got stuck inside the machine. Can you imagine his anguish when he discovered that he had made TWENTY CASES of labels with uneven cuts? Some labels had even been shipped! He immediately contacted the shipping company and had the labels intercepted, fixed the machine, and then made another 20 cases the next day. He took his experience with this one incorrect order to incorporate systematic and stringent quality processes, starting with the very first label on every order.

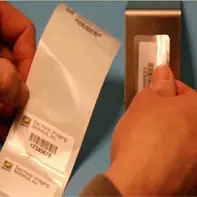

From the beginning, they wanted the company to be the best in the barcode label industry. They were convinced that careful selection of materials—matching the material both to the application and to the printing device—was the key element to success. Most printers and label converters did not have highly-developed material-matching skills, nor did they know barcode printing technologies. This gave the company an opportunity to sell highly customized labels for specialized applications. Satisfying customers with unique, innovative products continues to make EIM financially strong. Paul once told a newspaper editor, “The important question is not how fast we grow, but how much better we can become.” The phrase stuck and it has become the linchpin for us to focus our efforts and to grow our business with existing customers.

In 1988, Paul and Sue moved the business into rented space in an old silk mill in scenic downtown Keene. We experienced continued growth and were able to expand several times into other areas of the mill complex during the fourteen years we were there.

Growth required not only more space, but also additional machinery that would enable us to run long orders on some machines and short orders on others. This meant that we no longer had to interrupt long runs to fill emergency orders. Gradually moving from simple blank label products, we augmented our printing expertise to provide full printing services for our customers. We added one-color printers and then advanced equipment that prints four colors, laminates, and die cuts in a single pass—all while handling custom designs that incorporated complex variable data.

Through the years, we have constantly updated and added equipment in order to successfully meet customer requirements. In order to maintain our leadership position, we make regular investments in technology, research, development and tooling. We do thorough in-house testing to find the optimal compatibility between labels, printing ribbons and printers, thus assuring the best possible performance of our products. We work closely with our suppliers to keep informed about new products and cutting-edge developments.

We also invest significantly in recruiting and developing our employees. Early on, we realized that we had people who had more experience and more ability than in other label companies. It seemed only natural to call them our “Label Experts.” Paul seized on this clever epithet and was determined that this was a concept he wanted to emphasize and capitalize upon. Perhaps you’ve seen the phrase on our website and our marketing materials?

In 1999, Paul and Sue’s son, Alex Henkel, joined the company full-time. We eventually outgrew our mill space and started the search for a suitable relocation space. In 2002, EIM acquired an 11-acre parcel with an open-span freestanding building that allows flexible workflow changes as customer needs change. Over time, Alex gradually took over daily operations and strategic planning. One of his first mandates was to replace separate accounting and production management systems with a single, unified system. In 2007, Alex and his wife, Heather Bell, purchased the company and embarked on a process of long-range planning aimed at the next twenty years of the enterprise.

We still specialize in quick response and what Alex calls “engineered labels”—labels specifically engineered on an individual basis to satisfy customers who cannot find the specialized labels they require anywhere else. We take an industry-by-industry approach to solving challenging and unusual label applications. We realize that barcode labels are often critical to customer operations where essential testing, accounting, manufacturing and distribution functions occur. That makes reliability, consistent product quality and conformance to quality standards our top priorities.

While Paul and Sue fully retired at the end of 2006, they still enjoy getting regular updates about the company (including this newsletter!). At one point, Paul said “One of the biggest sources of enduring pride Sue and I have is the continued success of EIM.”

________

We want to thank Paul Henkel for his participation in this article and for his major impact on our company’s development.