Front-end consultants…Back-end support. We do far more than just supplying bar code labels. Whether you’re looking for a quick solution to set up and start barcode label printing, or you have a uniquely tough problem that requires a durable custom label, EIM’s technical support will help you find just the right answer. Once you’re up […]

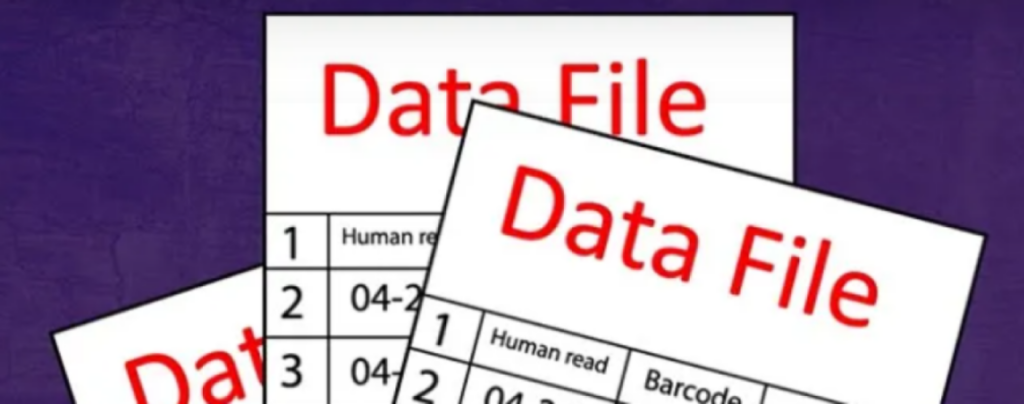

Submitting Your Barcode Data File Preparing your barcode data file properly in Microsoft Excel or a similar spreadsheet program can ensure the labels & barcodes you receive are exactly as requested, and can potentially expedite your order. Here’s how it works: For variable barcoding, place your coding in a column, like this: *This order will […]

A Comprehensive Guide to Everything Labeling: Getting Started Barcode Labels Are you thinking about using labels for the first time? Wondering how serialized barcodes work with your inventory? Or perhaps you need a refresher? Whether a naïve first-timer or a seasoned customer, you’re in the right place for a full rundown on labels and barcodes. […]

Barcode labeling is everywhere. Barcodes are everywhere! Supermarket products, library books, packages, and smartphone screens. Many forms of barcode languages, or symbologies, can be found in barcode labeling. That number continues to increase as technology becomes more sophisticated. Through barcoding’s evolution, symbologies were purposefully designed for solving particular problems, sometimes each uniquely linked to specific […]

If you can’t find the answer you need among our frequently asked label questions, The Label Experts are just a phone call or email away. Ask us anything! Do you sell labels? Yes! We sell made-to-order labels to industries ranging from laboratory to manufacturing, to warehouse and beyond. We have access to hundreds of specialty […]

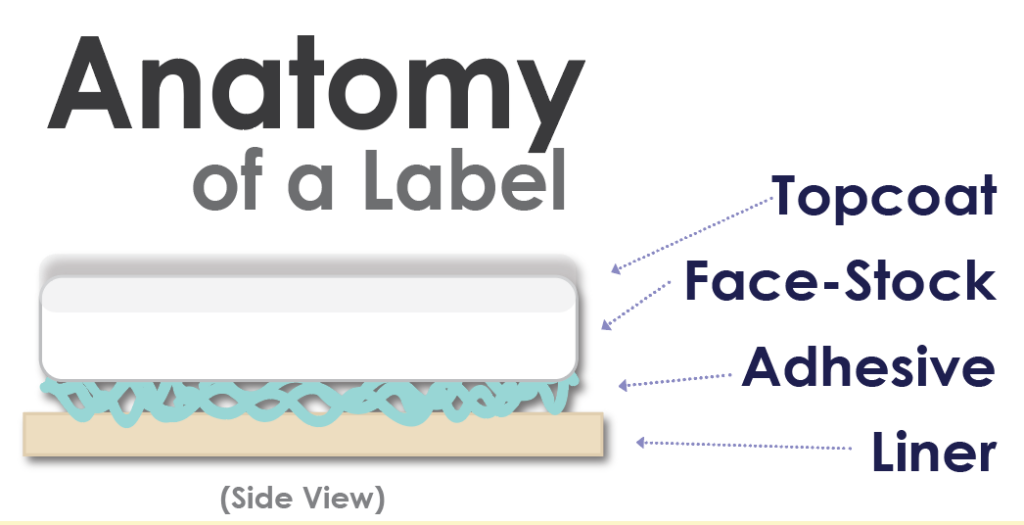

Appearing simple at first, adhesive labels are deceivingly complex creatures. Much more than mere “stickers”, labels are designed to carry information. Whether this info is expressed through a barcode or written text, the label’s main purpose is to create a smooth flow of information transfer for any operation. The goal is to simplify, removing the […]

EIM provides series of WHITE PAPERS, or technical guides, to be used by our customers as resource tools. In our Barcode White Paper section we have added articles about specific barcodes and the applications where they are most popular. By reading through our materials, you will learn how to recognize certain codes, how to print […]

This easy to follow printer set up video teaches you how to calibrate your TSC TX600 desktop label printer. You can follow the steps below to calibrate and start printing labels as soon as you unbox your new TSC TX600. How to Calibrate Your TSC TX600 Label Printer You will need: a printing ribbon, take-up […]

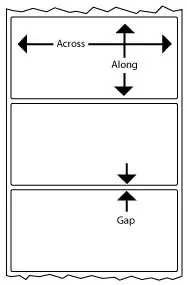

Don’t let label layout and the idea of ordering labels scare you. The Label Experts at Electronic Imaging Materials, Inc. can easily help you define not only the right label material, but the right label size and label format to fit your application and printing requirements. Label Layout A typical label or tag has a […]

Explaining the Different Barcode types Here’s an easy way to understand how barcodes work: think of them as a more technologically savvy way to transfer strings of characters. They are basically a license plate that is linked to data files. These strings of characters can designate all types of information. Rather than manually writing and […]

Important initial information: Rack Label spreadsheet format: Totem Label spreadsheet format: If you still have questions about setting up your warehouse data files, send The Label Experts your questions.

Print barcode labels with an in-house printing system, it’s easier than you think. However, if you’re like some of The Label Experts prior to working for us, you may think that printers are evil or scary. Why is it that they can spit out misprints and chew up sheets in their attempt to mock you […]