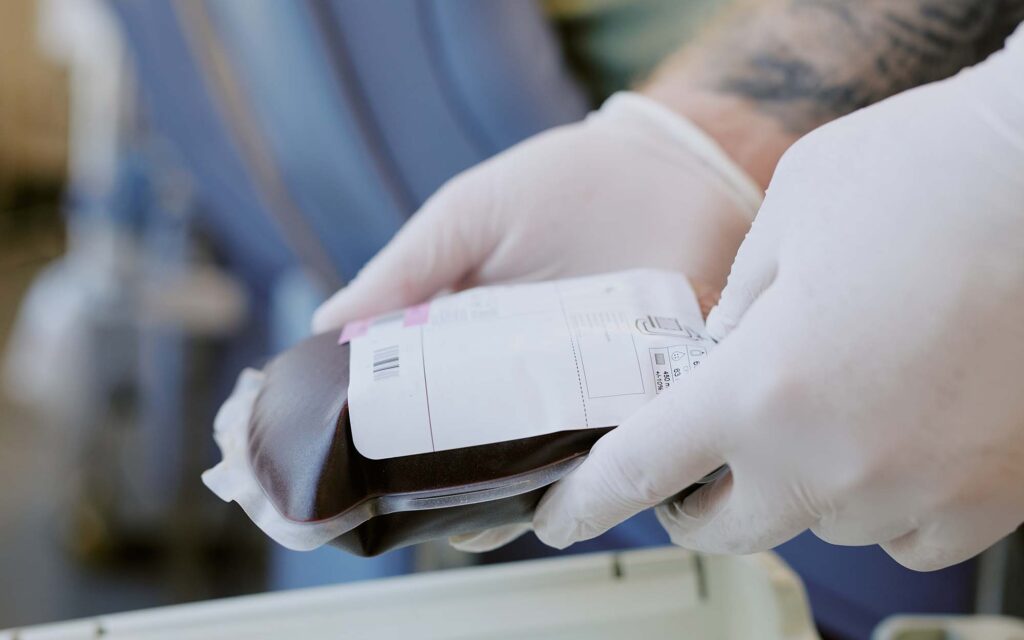

Medical device labels don’t have the luxury of failing quietly. When a label fades, lifts, or smears, the consequences can ripple across product recalls, compliance violations, and patient safety risks. That’s why innovation in medical device label materials is an advantage for manufacturers serious about quality and durability.

In this article, we’ll explore how new materials and technologies are pushing the boundaries of what medical device labels can endure. From high-heat sterilization to aggressive chemicals and constant handling, we’ll show you what works, what doesn’t, and how the right materials can dramatically reduce your label failure rate.

Why Material Selection Matters for Medical Device Labels

Medical device labels are exposed to conditions that would destroy an average label in seconds. Think autoclaves, ethanol baths, refrigeration, and abrasion during transportation and storage. Choosing the right medical device label materials is the first line of defense against these stressors.

More than a piece of plastic with ink, each label includes:

- Substrate: The base layer that determines flexibility, chemical resistance, and heat tolerance

- Adhesive: Tailored to bond with a wide range of surfaces, including plastics, metals, and glass

- Topcoat or Laminate: Protects the print from smearing, scratching, and environmental damage

If any of these components underperform, the entire label becomes a liability.

Material Innovations Driving Durable Medical Labels

Recent advancements in material science have opened new doors for durable medical labels. Manufacturers can now choose from a broader range of high-performance substrates and adhesives engineered for life inside a lab or hospital.

High-Performance Substrates

New-generation polyesters, polypropylenes, and polyimides offer greater resistance to heat and chemicals. For example:

- Polyimide films can handle temperatures above 500°F and are ideal for steam sterilization.

- Topcoated polyester films deliver strong solvent resistance and are a popular choice for high-contact environments.

These advanced films retain their shape, adhesion, and legibility even after repeated exposure to harsh processes.

Medical Label Adhesives That Endure

Traditional adhesives often degrade under exposure to sterilants like hydrogen peroxide or ethylene oxide. Today’s medical label adhesives include:

- Cryogenic adhesives that perform in ultra-low freezers without becoming brittle

- Acrylic-based adhesives optimized for surface energy variability across different device materials

- Aggressive bonding formulations designed for low-surface energy plastics

These engineered adhesives offer peace of mind that labels will stay put, from packaging to point-of-use.

Protective Coatings and Laminates

Print durability is just as crucial as adhesive strength. New topcoats can resist:

- Xylene and alcohol-based chemicals

- Autoclave cycles and gamma sterilization

- Mechanical abrasion during handling and shipping

Combining the right coating with proper handling practices (such as avoiding label contact before chemical exposure dries) ensures long-term readability and barcode accuracy.

Common Applications and Matching the Right Material

Not all medical environments are created equal. Matching the material to the use case is the key to label longevity. Selecting the right combination of substrate, adhesive, and coating can make the difference between a label that fails and one that performs flawlessly throughout its lifecycle.

Durable Labels for Autoclaving

Devices that must undergo steam sterilization require polyimide or heat-stabilized polyester substrates. These materials maintain structural integrity and legibility under high heat. Pair them with adhesives rated for extreme temperatures to ensure the label doesn’t lift, blister, or delaminate during repeated autoclave cycles.

Cryogenic & Refrigerated Storage

Labels used in cold-chain applications must be built for extreme environments. Flexible, moisture-resistant films paired with cryogenic adhesives stay tacky and secure even at sub-zero temperatures. This combination prevents peeling and ensures barcode readability throughout storage and retrieval.

Solvent-Heavy Environments

Pathology and diagnostic labs often rely on chemicals like xylene and ethanol. These solvents can quickly degrade inferior labels. Solvent-resistant substrates and protective laminates guard against staining, smearing, and fading. This ensures barcodes remain scannable and text stays legible after chemical exposure.

On-Device Labeling

Labels applied directly to medical devices must adhere to challenging surfaces, including curved or textured plastics. In these cases, ultra-aggressive adhesives and conformable, thinner films are key. They maintain adhesion without lifting or edge curling, even after handling and sterilization processes.

Choosing the right medical device label materials is about precision, testing, and experience. If you’re unsure whether your current labels are holding up or if you’re launching a new product, Electronic Imaging Materials can help.

How to Evaluate Medical Device Label Materials for Your Application

With so many options available, how do you choose the right combination? Start by understanding that no single solution fits every situation. The right label material depends on how and where it will be used, what it needs to survive, and the regulations it must meet. Here’s a breakdown of what to consider:

1. Audit Your Use Environment

Evaluate the environmental conditions your label will face—heat, cold, chemical exposure, and physical handling. Labels in sterilization chambers or cryogenic freezers need materials and adhesives that won’t degrade, lift, or fade under pressure.

2. Verify Surface Compatibility

Not all surfaces interact the same way with adhesives. A label that bonds perfectly to glass may lift or shift on a plastic catheter. Matching the adhesive chemistry to the device surface ensures consistent adhesion and reduces the chance of label failure.

3. Test in Real-World Scenarios

Controlled lab testing is a good starting point, but doesn’t always reflect daily operations. Put your labels through the same processes they’ll face in the real world—sterilization, refrigeration, shipping, and actual handling. Only then can you confirm they hold up across every phase of the workflow.

4. Don’t Forget Regulatory Fit

Even the most durable label isn’t useful if it doesn’t comply with regulatory standards. Make sure your material, adhesive, and print technology meet FDA, MDR, or ISO requirements for your device class. A well-performing label must also be a legally compliant one.

Environmental and Regulatory Considerations

Sustainability and compliance can work hand in hand. Leading medical device label materials are high-performing and environmentally responsible:

- RoHS- and REACH-compliant, meeting international standards for hazardous substances

- Formulated without halogens or other restricted chemicals

- Offered with eco-conscious options like recyclable liners or reduced-waste constructions

Crucially, these innovations don’t compromise durability. They’re engineered to meet FDA and global compliance standards, making them a smart choice for manufacturers who prioritize performance and the planet.

Ready to Label Smarter, Longer, and Stronger?

Electronic Imaging Materials understands that medical device label materials are the glue (literally) holding your product identification strategy together.

From custom material testing to compliant printing solutions, we deliver everything you need to create labels that stick, survive, and perform. Whether you’re reworking a current label or preparing for a product launch, we offer expert support every step of the way.

Let’s build durability into your labeling strategy. Contact us today for tailored material recommendations and proven solutions for every device you make.