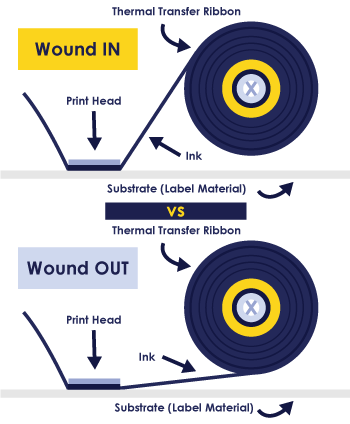

When you place an order for printing ribbons, we will ask you what printer model you are using and whether the ribbon is coated side in (CSI) or coated side out (CSO). This refers to how the printing ribbon comes off the roll and feeds through a printer.

Printers like Zebra and TSC use the popular format of CSO. This means the waxed side of the inked ribbon faces the OUTSIDE of the roll. Other printers like Datamax or Sato are commonly designed the opposite way and use CSI ribbons. Some printers will work with ribbons in either CSI or CSO format. (We’ve also found ways to feed almost any ribbon over the various rollers to make use of either type.)

So why is it so important to know how your ribbon is wound? Thermal transfer printing depends on the waxed side of the printing ribbon coming in direct contact with the label so that when heat from the printhead is applied to the back of the ribbon, it transfers an image to the label. If you don’t have the right (face) side of the ribbon meeting the face of the label, you won’t get an image and the waxed ink can damage your printhead.

Here’s a Neat Trick: If you don’t know which way your printing ribbon is coated, there is an easy test you can do. Simply take a piece of scotch tape and apply it to the outside of the roll. When you peel the tape off, look for the ink to come off with it. If it does, we call that a CSO ribbon. If it doesn’t come off with the tape, try the other side of the ribbon. The ink should come off: you have a CSI ribbon. The side of the ribbon that doesn’t come off with the tape is called the carrier or film backing.

EIM maintains an extensive database of thermal transfer printer specifications and will help you pick the Right Ribbon Formula and the Right Format. Even if you just need help installing your thermal transfer ribbon, simply give us a call (800) 535-6987 or Contact Us Here. As always, EIM is here to help make printing labels easy!