We can’t lie, sometimes when a customer reaches out for freezer rack labels, it’s just a normal day at EIM. But when an indie ice cream maker in California called in needing help labeling a new cold storage warehouse, the foodie Label Experts perked up!

Have we told you how passionate we feel about ice cream here at EIM? In terms of serious contemplation, our #1 is labels, followed very closely by our neck-in-neck foods of choice, ice cream and coffee. We keep our breakroom stocked with blueberry ice cream sandwiches year round. And come summer, you’ll find a small crowd of Label Experts hanging out on our lawn for mid-week gelato breaks!

While we swapped favorite ice cream flavors with our new favorite client, we set about finding the perfect barcode labels for their new cold storage facility. When it came to materials, our Label Expert on the job was pretty confident that our Freez-R-Mark material was the best of our cold temp options for their freezer set up. After some testing, our ice cream makers were able to confirm that the freezer rack labels held up in their cold warehouse conditions.

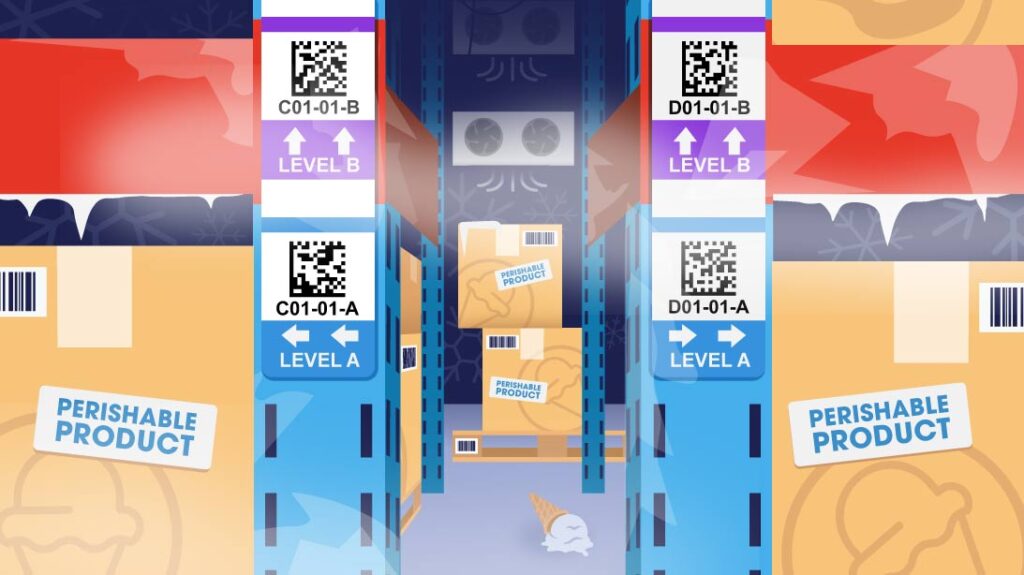

Next came finalizing their print files. With multiple levels of food storage in their freezer and countless bins of creamy goodness to keep track of, they had a vision for exactly how to organize their inventory. And that vision…. was complicated. So complicated that their Label Expert took a different approach than we normally do to inventory storage. (Complicated inventory tracking? No problem! We are pros at helping vet and check clients data files for accuracy.) This time, our Label Expert took a look at the system they were trying to establish, their ideal label size inside their freezer space and concluded that a little brainstorming was in order!

The Label Expert explained how the amount of data they were trying to include on their freezer rack label was getting a little too complex to be easily represented in the mid-sized totem freezer label they were eyeing as their preferred option. They presented a few ideas on how to simplify the in-freezer inventory management system to make tracking easier. After taking the Label Expert’s ideas to their freezer manager, our client got the okay to go to print with a newly simplified system for inventory tracking.

The end result? A freezer proof totem label perfect for long distance scanning!

After their positive experience during this first order, they ended up referring us to a sister freezer warehouse in middle America… and they in turn referred us to their cold chain counterpart in Wisconsin. As we were wrapping up their made-to-order freezer rack order, we were starting on a custom collection of color-coded data matrix inventory tags for their private labeling ice cream facility just down the road. We’ve never helped so many flavorful customers in a row! When we asked what was prompting this influx of pass the potato label orders, the through line was our Label Expert’s ability to take what had worked for the last freezer manager, and adapt and customize sizes, barcodes, and formatting quickly for the following freezer manager who was dealing with a completely different facility layout.

Whether you’re dealing with complicated inventory management or frigid storage conditions you think are un-labelable, reach out to The Label Experts for help!