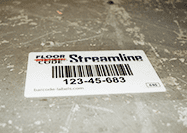

When it comes to floor labeling, we’ve seen a thing or two in our many years working with various warehouse customers. So, while our FloorCodeTM Streamline labels are rugged and reliable, there are some factors that can make—or break—its success in your warehouse. Let’s get into some of the dos and don’ts to make sure your floor labeling solution lasts as long as possible! > Want a more condensed version? Check out this infographic!

Prepping Your Floor for Label Shields

While installing these labels is easy and non-damaging to your floors, a little prep-work goes a long way. When preparing the floor (or rack, or whatever you decide to stick FloorCodeTM Streamline on), be sure to sweep away any loose dirt or debris from the surface. Also, a thorough clean with a general-purpose cleaner is important. The cleaner the surface, the better—FCSL should bond completely to the floor, not to surface contaminates, like dirt, oils, grime, etc. Let the surface dry completely before applying the label and shield.

Floor Labeling Application Tips

1. Avoid using strong chlorine or citrus types of cleaner for prepping the surface.

2. Avoid applying over floor seams, joints, or rough and uneven surfaces like asphalt.

3. Do not apply on top of other floor markings that may deteriorate over time.

4. When placing the laminate over the label, leave about ½” of laminate beyond the label edges.

5. Tamp it down with at least 250 pounds of weight. A forklift left sitting on top works!

6. Wait 48 hours before allowing regular traffic (apply on a Friday so it can sit over the weekend).

Getting the Most Out of Your Floor Labels

FloorCodeTM Streamline’s high-impact resistant makeup can handle the rigors of extreme traffic and heavy equipment, while its thin profile reduces the likelihood of pallets catching the edges. These are super durable, HOWEVER, no label is 100% destruction-proof. We’ve seen more than one forklift driver see these as a personal challenge to try to rip up and if the intent is there, it can be done. But with proper care and respect, these labels will last.

Floor Label Maintenance and Use Tips

7. Easy to clean—just wipe off dirt & grime

8. Not suitable for long-term outdoor exposure, FloorCodeTM Streamline polycarbonate shields aren’t UV resistant.

9. Do not drag pallets along the floor. If a protruding nail on the bottom of a pallet will scar a concrete floor, a 5 mil polycarbonate shield will likely not stop that same nail either!

10. If you have to relabel your warehouse floor in the future, FCSL is easy to remove. Simply place a small scraper blade under the shield and pull up at a 180° angle.

11. Do NOT tell your warehouse staff these are indestructible!

As with most of our label solutions, FloorCodeTM Streamline can solve one of the most common labeling challenges in the logistics industry. Give The Label Experts a call at 800.535.6987 to see how we can help you solve your floor labeling challenges, or to find out how you can get samples to test out these durable floor labels in your own facility.