In many laboratories, keeping track of samples, reagents, and equipment is an everyday challenge. Whether dealing with delicate slides, small vials, or large equipment, a reliable system of labeling makes a world of difference. If labels peel off, smudge, or become unreadable, it can slow down research, cause confusion, and even affect compliance with important standards.

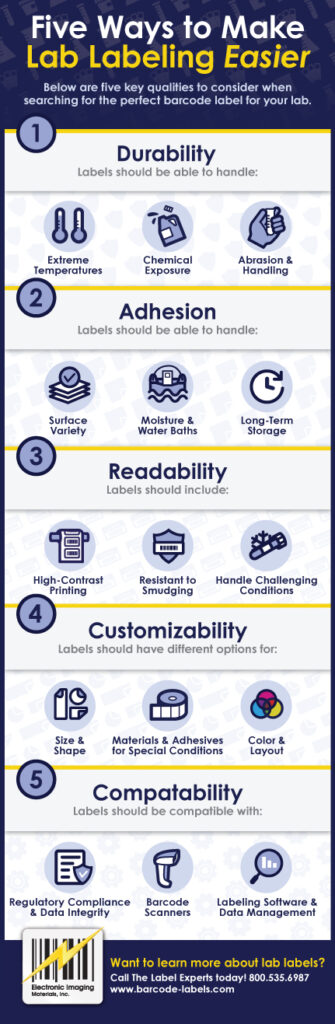

To avoid these headaches, knowing what to look for when choosing labels is important. Below are five key qualities to consider when searching for the perfect barcode label for your lab. By focusing on these features—durability, adhesion, readability, customizability, and compatibility—you’ll be well on your way to maintaining proper labeling in the laboratory. > Want a more condensed version? Check out the infographic down below!

1. Durability

Laboratory environments often push materials to their limits. Samples may be stored in extreme temperatures, soaked in water baths, or exposed to harsh chemicals. It’s essential that laboratory labeling solutions withstand these conditions without fading, smudging, or peeling. After all, the last thing a lab manager wants is to lose track of a valuable sample because its label becomes unreadable.

Extreme Temperatures

Many labs deal with cold storage, including freezers, cryogenic conditions, and even storage in liquid nitrogen (LN2). Cryogenic storage, especially in LN2, can reach temperatures as low as -196°C. Not all labels can handle this. Some labels remain stable when applied at room temperature but fail when placed directly on already-frozen surfaces. In these cases, a special material designed for cryogenic conditions is needed. Good laboratory labels hold up even when applied to a pre-frozen vials, ensuring the text and barcodes remain intact throughout freeze-thaw cycles.

Chemical Exposure

Another challenge in labs is exposure to strong solvents, acids, or cleaning agents. If the label ink smears or the adhesive weakens, the label can become useless. Choosing labels that resist harsh conditions is key. Certain materials are developed specifically for chemical labeling in the laboratory, allowing them to stay legible even after contact with solvents, ethanol, or disinfectants.

Abrasion and Handling

Some labels undergo frequent handling. This is common in labs that move samples from station to station or perform repeated washes. A durable label resists scratching and rubbing, ensuring the barcode or text remains clear. By picking a label with proven durability, you set the stage for smoother, more reliable laboratory labeling over time.

2. Adhesion

In any laboratory setting, surfaces vary widely. From smooth glass vials and plastic tubes to metal racks and cardboard boxes, each surface presents a different bonding challenge. Labels must stick firmly and remain attached under all conditions. If a label peels off a vial and drops into a centrifuge, or falls off a plate and mixes with another sample, it can create confusion and waste precious resources.

Surface Variety

Good adhesion means a label can attach securely to vials, slides, and plates without curling at the edges. Some adhesives are optimized for cold surfaces, while others are better for dry, room-temperature conditions. Understanding your lab’s conditions makes it easier to select laboratory labels that bond well without needing frequent reapplication.

Moisture and Water Baths

Consider water baths and high-humidity environments. Labels should withstand moisture without losing grip. A good laboratory labeling solution remains stable in water baths, ensuring that the barcode and text stay put no matter how steamy the environment gets.

Long-Term Storage

Some samples sit in storage for months or even years. If the label loses adhesion over time, key identifying information may be lost. High-quality adhesives are formulated to resist aging, guaranteeing that labels won’t gradually slide off over extended storage periods.

3. Readability

A barcode label is only useful if it can be read easily. In a busy laboratory, staff may not have time to struggle with a scanner that fails to pick up a faint barcode. Labels must produce crisp, clear prints with good contrast so that scanning is fast and error-free. This attention to readability improves workflow and prevents mistakes caused by guesswork or manual data entry.

High-Contrast Printing

Clear, bold text and barcodes ensure accurate scanning. Whether your lab uses handheld scanners or automation systems, the label should present a code that’s easy to detect. Specialty coatings or topcoats can enhance print quality, ensuring ink does not bleed or fade.

Resistant to Smudging

Some printing methods are more prone to smudging than others. If labels smudge in the presence of solvents, water, or even body oils from handling, the barcode might become unreadable. Smudge-resistant or chemical-resistant coatings help preserve clarity, enabling smooth laboratory labeling processes day in and day out.

Handling Challenging Conditions

Labels need to remain legible despite exposure to cold, heat, or chemicals. This could mean enduring repeated freeze-thaw cycles or surviving autoclave sterilization. An ideal label’s printing surface and ink remain stable, keeping barcode lines sharp and scannable at all times.

Working with lots of chemicals? Along with these factors, you need to make sure your laboratory labels are meeting regulatory standards. Learn more about how to ensure this.

4. Customizability

Every laboratory is different. Some rely on small vials for genetic samples, others work with large beakers, and still others have unique workflows or storage conditions. Off-the-shelf labels may not always fit these diverse requirements. That’s where made-to-order solutions come into play. Having the option to customize labels ensures they meet the lab’s specific needs, saving time and reducing frustration.

Size and Shape

A vial’s surface area might be very small, requiring tiny labels that still hold a barcode and some text. In contrast, large storage boxes may need bigger, easy-to-spot labels. Custom sizes guarantee a perfect fit, so the label neither overlaps nor leaves wasted space.

Color and Layout

Color coding can improve efficiency. Some labs assign a certain color label to a specific department, study, or hazard level. Custom colors and layouts help technicians quickly identify what’s what. Also, the ability to include multiple lines of text, batch numbers, or special symbols ensures that each label conveys all necessary information at a glance.

Materials and Adhesives for Special Conditions

If your lab deals with unique chemicals, extreme cold, or other unusual conditions, you will need specialty materials. Made-to-order options let you choose materials designed for cryogenic conditions, autoclaving, or harsh chemical exposure. This way, the label always suits the task at hand, rather than forcing a one-size-fits-all approach.

5. Compatibility

Even the best laboratory labels won’t help much if they don’t play nicely with your existing tools. Compatibility ensures that labels integrate seamlessly into barcode scanners, labeling software, and inventory management systems. This leads to smoother workflows, fewer scanning errors, and easy data sharing between stations or departments.

Barcode Scanners

A reliable barcode label must match the lab’s scanning technology. Some scanners read only certain barcode types or symbologies. Others might struggle with reflective surfaces or small print. Selecting labels that produce barcodes easily recognized by your scanners saves time and reduces frustration.

Labeling Software and Data Management

Modern labs often use software to design labels, track inventory, and record sample data. Many also rely on a Laboratory Information Management System (LIMS) to keep all data and processes in sync. Compatibility with these tools means you can print labels in-house, on-demand, and whenever you need them, while ensuring that barcode information flows seamlessly into the LIMS. This flexibility is vital if conditions change, if you run out of a certain label size, or if new projects come up that require different designs.

Regulatory Compliance and Data Integrity

Proper labeling supports compliance with regulations and standards. By choosing labels that integrate with inventory tracking systems, you help ensure that each sample’s journey is recorded accurately. This reduces the risk of mix-ups and supports strong record-keeping. Reliable labeling contributes to a clear chain of custody, making it easier to respond to audits or reviews and reinforcing the lab’s good standing.

The Bottom Line

The right barcode label can make all the difference in how smoothly your lab runs. By focusing on key qualities—durability, adhesion, readability, customizability, and compatibility—you set your lab up for success. These features ensure that labels remain secure, easy to read, and ready to integrate with your existing tools.

As you review your current labeling system, consider whether your labels meet these standards. “Are they holding up in extreme cold or chemical environments?” “Do they remain readable after multiple freeze-thaw cycles or exposure to solvents?” “Are there made-to-order solutions available for your unique setups?”

By asking these questions and seeking labels designed specifically for laboratory conditions, you can streamline sample tracking and ensure that regulatory compliance and quality standards are met. Investing in top-quality laboratory labeling solutions may seem like a small step, but it can have a big, positive impact on your lab’s efficiency and reliability.

Streamline Your Lab Labeling with Electronic Imaging Materials

Ready to upgrade your labeling system? Contact us today for expert guidance and high-quality, made-to-order laboratory labeling solutions—see the difference for yourself!