So what do you do when you get some label samples to test in your application? You may be curious to find out just how durable the print will be. No problem! It’s easy! Simply take a trusty old #2 pencil out….that is, if you even use pencils any more. You will need to use the eraser end of the pencil to do the test. A pencil-top eraser is usually better than a cube-shaped eraser because you can use more pressure while you are rubbing the rubber over the printed image.

So what do you do when you get some label samples to test in your application? You may be curious to find out just how durable the print will be. No problem! It’s easy! Simply take a trusty old #2 pencil out….that is, if you even use pencils any more. You will need to use the eraser end of the pencil to do the test. A pencil-top eraser is usually better than a cube-shaped eraser because you can use more pressure while you are rubbing the rubber over the printed image.

When you rapidly rub the print trying to destroy it, you are creating heat. The combination of the abrasion and heat—applied for about 20 seconds—will typically rub out the image (that is if your arm holds up). This often happens with paper labels and wax ribbons. When it comes to more durable label materials however, such as polyester and most plastics, we will be suggesting you use a resin or wax/resin ribbon blend which we have thoroughly tested so we can recommend the most durable combination. NOTE: Our UV inkjet ink system will produce similar results.

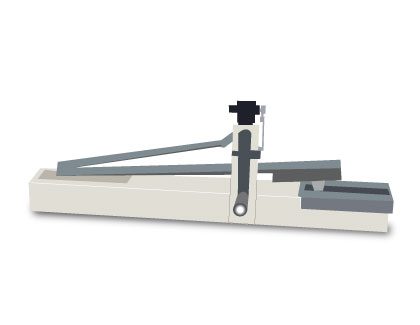

For scratch resistance? You can use the edge of a coin or ruler. Chances are, with the right ribbon, you will destroy the material before you destroy the print!

For scratch resistance? You can use the edge of a coin or ruler. Chances are, with the right ribbon, you will destroy the material before you destroy the print!