Uncover the challenges and solutions when selecting weatherproof labels that won’t curl at the edges.

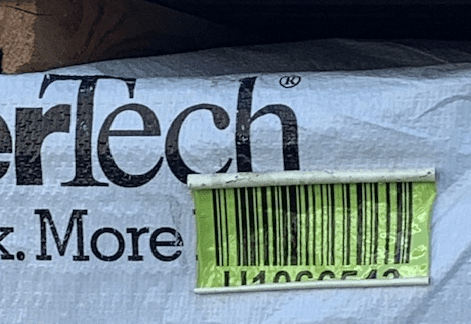

Let’s take a closer look at some issues a lumber company client faced with outdoor labels. They encountered problems like edge curling and weather durability.

What they needed their labels to do:

- Adhere to a variety of irregular surfaces

- Withstand outdoor high-UV

- Stay on during high-wind

- Handle Nebraska’s tough weather conditions

It took some trial and error from The Label Experts, but the outcome really stuck!

The Right Label Material: The Evolution of Selection

It took us three tries.

Initially, The Label Experts suggested testing one White Plastic material that had demonstrated success for previous clients. However, this material didn’t provide the durability for our lumber company’s specific outdoor labeling requirements.

Next, we tried another White Plastic offering a more aggressive, high-tack rubber adhesive, plus a rating for 1–2-year outdoor use. While this material works for some applications, it still fell short.

In the end, we turned to a top-coated White Plastic which has proven to be effective for many applications, including wood and carpet backing. This material features an ultra-aggressive adhesive that can withstand outdoor conditions as well as the topcoat for protection against UV exposure, making it the best choice for their outdoor equipment labels and irregular surfaces.

The Role of Ink: Unexpected Factors Affecting Label Performance

Our investigation into the edge curling issue led us to consider the role of the ink in the label’s performance. UV ink undergoes a process known as “curing,” which involves the ink contracting slightly. This contraction could potentially lead to edge lift and curling, as observed in the lumber company’s labels. While this unexpected factor was initially overlooked, it serves as a valuable lesson in understanding the various elements that can affect label performance! Leaving a 0.25″ border around the tinted label reduced the edge curl. This small adjustment made a significant difference in preventing curling and ensuring the label stays securely in place.

Eureka! That’s the winning combination.

This journey of trial and error emphasized the significance of reassessing and adapting label material selection to meet specific needs. We’ve learned it’s essential to consider factors like adhesive strength, durability, ink, design, and weather resistance when selecting the perfect label material for outdoor equipment.

Let a Label Expert help find the right solution for YOUR specific needs. Collaboratively, we can boost the resilience and longevity of your outdoor equipment labels, let’s make sure they can endure the rigors of inclement weather and rough surfaces!