GHS (Global Harmonized System) is a program developed to organize the classification and labeling of chemicals around the world. These international standards began in 1999 when the United Nations Economic and Social Council determined the need to better control the transport of dangerous goods. GHS defines possible health, physical, and environmental hazards associated with chemicals based on a new set of categories that must be included on both labels and Material Safety Data Sheets (MSDS) ― now to be called SDS.

GHS is not a regulation, but rather a guide for chemical safety. The United States Occupational Safety and Health Administration (OSHA) chose to update their Hazard Communication Standard (HCS) to adopt the GHS guidelines. It is important to understand GHS—whether you work in a manufacturing facility, an industrial environment or a hospital lab—because it is part of the right-to-know laws for employees exposed to hazardous and toxic chemicals

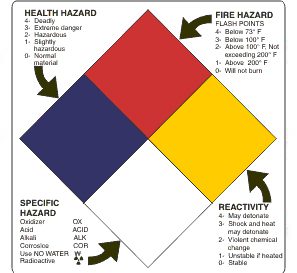

Over several decades the number of safety warning symbols used on safety signs, labels and MSDS documents had become overwhelming. It seemed like anyone could create their own design and some symbols were for very unique conditions. As a result, it was often difficult to understand label warnings.

The US EPA and OSHA has designated the use of nine RED AND BLACK diamond-shaped pictograms (symbols) that will cover an easier-to-understand range of hazard classes. To make the transition easier, we may still see the old red, blue, yellow and white diamond chemical hazard layout but the new symbols will be required.

Can you correctly identify these symbols?

Click here to learn what the nine symbols mean.

Besides a pictogram, every GHS Label must include the following sections:

- Product Identification

- A signal word of “Danger” or “Warning” (The word “Caution” has been discontinued)

- Physical, Health, and Environmental Hazard Statements

- Supplemental Information

- Precautionary Measures

- First Aid Statements

- Name, Address and Telephone of the Supplier Company

- Other steps in the implementation process include performing a chemical inventory, acquiring updated SDS forms, updating the labeling on all chemical containers and maintaining the GHS program.

Electronic Imaging Materials, Inc. can help with your GHS labeling needs:

- Do you need to re-label an existing product in the warehouse waiting to be shipped?

- Do you need to create new labels for materials in production?

- Do you need labels that are resistant to harsh chemicals, can endure extreme temperatures or need to withstand years of outdoors exposure?

- Our Label Experts work with you to select labeling products for your specific needs. We have tailored solutions for a wide variety of manufacturing and industrial settings.

The biggest issue we have uncovered is that most people do not own multi-color label printers. If you have a color laser or inkjet printer, then this is not a problem and our BarTender® Label Software is already programmed for GHS. Otherwise, we can print your chemical labels for you, laid out to meet GHS standards. We can also partially print labels with one to nine of the red diamonds so all you have to do is add variable information printed in black. (NOTE: You are not allowed to “black out” any used diamonds.)

If you have any questions about GHS requirements, please feel free to contact The Label Experts.