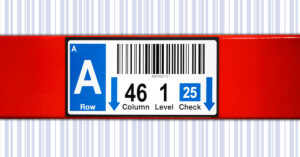

Appearing simple at first, adhesive labels are deceivingly complex creatures. Much more than mere “stickers”, labels are designed to carry information. Whether this info is expressed through a barcode or written text, the label’s main purpose is to create a smooth flow of information transfer for any operation.

The goal is to simplify, removing the effort, time, and expense involved with handwriting and human error. A label’s composition is made up of four distinct layers, and our extensive range of materials allows for a custom combination suitable for your label application. Whether preprinted or specially crafted by The Label Experts, why not learn about how labels can serve you?

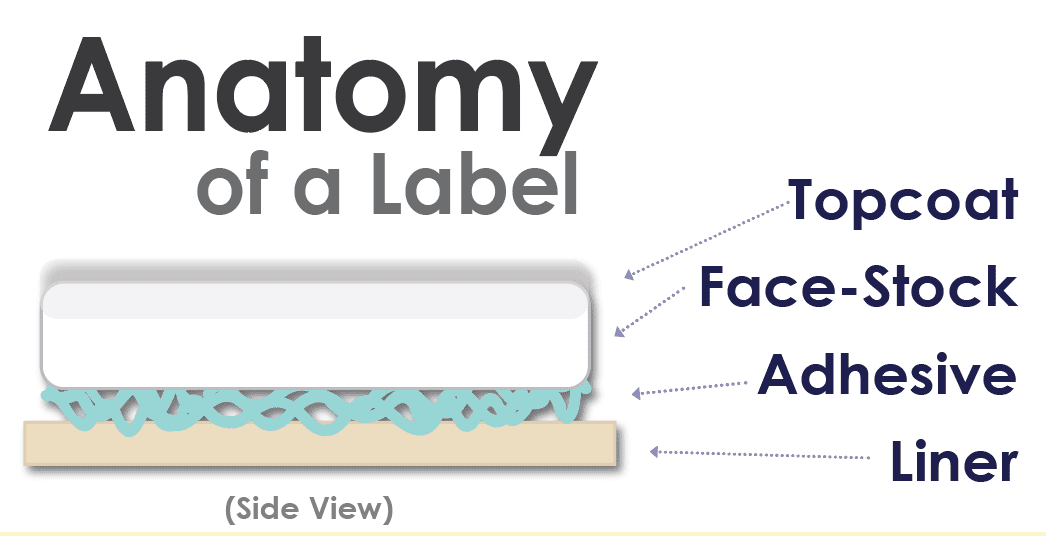

Label Layers

We here at EIM like to use an analogy for the layers of labels. Think of ordering a sub at your favorite sandwich shop. You tell the maker which bread, protein, sauce, and vegetables you would like. Labels work the same way. When you are specifying a custom order, it’s important to consider the four layers of labels: liner, adhesive, face-stock, and top coat.

> Feeling educated? Speak to The Label Experts today!

Topcoats

Identified as the top surface, this clear layer applies directly onto a face-stock. Using a top-coat for your label is not always necessary, but does serve useful purposes, such as enhancing ink adhesion and lamination. Extended exposure to UV and other conditions may require your label to have a topcoat to avoid ink upheaval. If you are requesting samples or a quote, you will be prompted for either a gloss or matte finish for your label. These are more or less for aesthetic purposes and would not alter the functionality of your label.

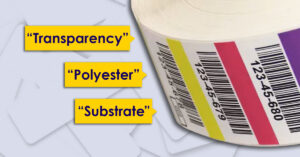

Face-Stocks

The material that you see and touch when using labels. More specifically, this is the layer that the machine prints on, and sticks to a desired surface through the adhesive on the back. EIMINC® offers an extensive selection of face-stocks, including papers, plastics and polyimides. The face-stock is equally as important as the adhesive to choose for correctly using the label under varying conditions.

Adhesives

Serves as the glue that holds the face-stock to its liner. Whether bonding your label to cardboard or glass, the adhesive is responsible for sticking under various conditions. Adhesives are generally grouped in three chemical categories: rubber, acrylic, and silicone. They also come in permanent and removable designs. Using the correct adhesive is crucial to ensuring the label meets your custom requirements and application.

Liners

Serves as the glue that holds the face-stock to its liner. Whether bonding your label to cardboard or glass, the adhesive is responsible for sticking under various conditions. Adhesives are generally grouped in three chemical categories: rubber, acrylic, and silicone. They also come in permanent and removable designs. Using the correct adhesive is crucial to ensuring the label meets your custom requirements and application.

Advanced Adhesive Label Lingo

Educating yourself on the composition of a label is essential. However, EIMINC® offers additional information that may further aid your understanding of label printing techniques. While these pages are not as critical to your ordering process, they give greater insight into custom properties and labeling services that we can offer when creating your product. Click through below to learn more about:

> Label Layouts

> Label Sensing

> Gaps, Repeats & Perfs

> Multi-Part Labels & Face Cuts

While our Getting Started guide may be useful, nothing can replace speaking 1-on-1 with one of The Label Experts. We are excited to assist you and help you come to a solution for your unique labeling needs.