Some time down the road you may find that you have need for what we call multi-part labels sets. Requirements like this typically involve labeling similar items that must be grouped together – such as a series of laboratory tests or small parts of a finished product. You may want a large label to put on your paperwork and smaller ones to identify the components that go into your products and experiments. This concept is also suitable for asset control whereby you have a permanent label in your files and copies for inventory or equipment.

> Want a more condensed version? Check out this infographic!

One way to solve this dilemma is to simply use labels that are all cut the same size. Your label software can be set up to print duplicate numbers or information in a series, for instance. They can be linked together by some common thread―such as a serial number―for the finished product or procedure. (Example: 0001, 0001, 0002, 0002, 0003 etc.)

But what if you really want to use labels cut to different sizes? Rather than getting labels of one size and printing them one after another, you really want certain label sizes to fit specific items.

You could, of course, get labels cut to various sizes and provided on separate rolls. If you are printing them on site, you would have to keep track of the numbering differences between the rolls and then try to carefully match the assorted labels. That can be a frustrating process, to say the least!

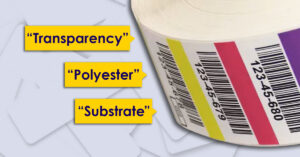

Sometimes it is easier to buy a special tool for your multi-part set. This is a particularly smart way to go if you are going to need a lot of labels. It’s much faster for a label converter like EIM to cut label sets with tools precisely engineered to fit your requirements. If you want to take a complete label set off the liner in one piece, we would add perforations between each label, so they can be pulled apart later. But if you’d rather get each label section totally cut apart, that can be done too. We can even design them with a combination of perfs and slits. We call this process adding FACE PERFS and FACE CUTS.

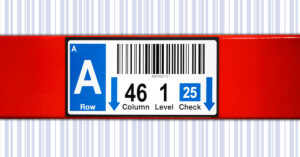

Multi-Part Tool

Dies with face perfs and face cuts let you marry groups of labels cut in different sizes. For instance, you need four labels that measure 1.00” x .50”. If you link them together you have a label set measuring 4.00” x 0.50”. Perhaps you also need some 2.00” x 1.00” labels. We can tie them as a group, so you would get four small labels and two larger ones butted together with no gaps.

Multi-part dies like this lend themselves perfectly to piggyback labels. In that case, we could engineer the tooling to cut the small sections through one layer of label material and leave them attached―as a whole set―to a second layer of material. Then you could easily apply the bottom layer to paperwork and peel off the various top sections as needed and apply them permanently to something else.

Sheet form laser labels are also a great format for multi-part labels. Not only can you get sets of labels in different sizes but also different shapes.

Extra Perf Tool Added

There is one more, rather cost-effective way, to deal with label sets. Let’s say you just want those four labels we mentioned before, cut to 1.00” x .50”. (Or you want one 2.00” x .50” label and two 1.00” x 0.50” labels). You only need a couple thousand label sets and that will hold you for several months. A converter like EIM may already have a tool that measures 4.00” wide by .50” tall (we do!). What we would suggest is to simply add a second tool that will perf or slit the 4.00” into three or four sections. This perf or slitting tool runs along the length of the roll only cutting the label material―not the liner. As with a special multi-part tool, if you want to keep all the parts linked together, we would use perfs. Should you want to peel each section off the liner separately, then we would use a slitting blade.

If you have any questions about Multi-Part Labels and Face Cutting, contact The Label Experts. They are ready to help you with any of your custom label formats.