What about ladder style barcodes?

Here’s a trick we’ve learned about ladder style barcodes to resolve printing problems involving linear barcodes like Code 39, Code 128, or UPC printed on thermal or thermal transfer equipment.

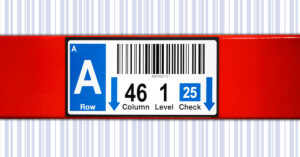

Have you ever been handed a label with someone complaining about print quality and not being able to scan a barcode? If you don’t have access to verification equipment, one of the first things to think about is “what direction was the label printed?” Let’s assume you don’t have a label with some of its liner to give you clues, so you are going to have to make a good guess.

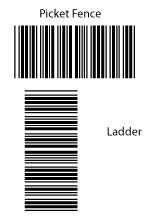

To do this, look at the beginning and ending bars in the symbol. With “picket fence” codes running across the label, the bars will look exactly the same since the energy used to print the barcode is evenly distributed across the entire code.

With “ladder-style” barcodes that are printed along the label, the print head energy changes as it is turned on and off to print each of the bars going down the length of the label. This is a particular problem for high density codes that rely on crisp bars and spaces for easy scanning. That on-off cycling sometimes doesn’t give the printer time enough to cool down between printing each element so the bars start to run together. One particular clue is if the last bar is thicker or thinner than the first bar. If this is the case, those bar variations are indicating one of two scenarios:

1.) If the last bar is wider (thicker) than the first bar, the heat from the print head built up as it went down the label and wasn’t consistently spread out. To correct this, decrease the heat and increase the print speed. You may also want to see if changing the label material and/or printing ribbon helps.

2.) If the reverse is true and the last bar is narrower than the first one, then the printer ran out of heat. For this situation, turn up the heat (if possible) and slow down the print speed. It may also help to eliminate any unnecessary print such as a business logo or heavy solid print areas used for stripes or dark backgrounds so you can conserve print head energy.

There are other issues that can create print quality problems like ribbon wrinkles or ribbon and label stock compatibility, but we will save those for a discussion in a later article. If you would like help in achieving better print results, contact The Label Experts.