When most people think about labels, they might picture the face-stock as their first image. Rightfully so, a label’s face-stock will typically make the first impression. Based on the type of material the face-stock (substrate) is made from, it can have a smooth, matte finish or a shiny, eye-catching appearance. Much more than just for aesthetic purposes, choosing the substrate material is critical to the end-use conditions that the label must withstand. Moreover, substrates provide the basis for printing, including images and barcoding. For applications that demand attention to detail, considerations for print quality and color must be taken into account as well.

Feeling educated? Request your free samples today!

Ask Yourself the Right Questions

To help narrow your search for the proper face-stock, try answering these three basic questions first:

1. What are the conditions the face-stock must withstand?

Understanding the end-use of the label is critical to knowing how much specialty is needed. Typical indoor applications may be easily solved by most paper face-stocks, but what about exposure to outdoor conditions? A specialty substrate such as polyester may be more appropriate, or alternatively, a top coat overlaminate. Extreme temperatures, weather, sunlight, grime, chemicals, and water are all external conditions to consider when labeling your surfaces.

2. Are color and transparency important?

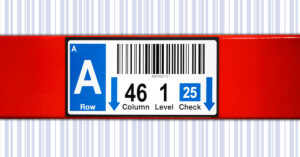

Almost every face-stock available comes standard as a white or silver material that allows for readable printing and scanning. However, it is not uncommon to have a different request. Labels can be preprinted with brightly colored fluorescent or clear face-stocks. Whether attempting to create a more attractive design or color-code for inventory purposes, it’s important to consider which material allows for such options when browsing.

3. What type of printing method & ink ribbon will be used?

If your substrate intends to display information or images, it’s important to consider how the material will be printed on. Certain digital printing technologies, such as thermal transfer, may be printed in-house with personal printers. The ribbon that coats the substrate with ink may need to compensate for flexibility if the applied surface is porous or rough. Perhaps a greater color scheme is needed for printing images? Substrates must be cleared for compatibility with types of printing methods.

Paper, Plastic, Polyimide, Shoot!

The two most common types of face-stocks used are papers and plastics. Plastics can be further categorized, split into polyesters, polypropylene, & vinyl. While this is not an exhaustive list of every substrate that EIMINC® has to offer, the materials listed below can give a good sense of direction on which type may be suitable for you. You may discover after describing your unique application to The Label Experts that they will recommend another type of substrate not listed below.

| Paper | Polyester | Polypropylene | Vinyl | Polyimide | |

|---|---|---|---|---|---|

| Common Surfaces | Indoor, shipping & packaging | Outdoor applications, machinery | Shelf & Bins, Freezer applications | Window decals & bumper stickers | PCB circuit boards & electronics |

| Chemical Resistance | Low | High | Medium | High | High |

| UV Resistance | Medium | High | Medium | Medium | High |

| Temperature Resistance | Low | High | Medium | Medium | High |

| Conformability | Low | Low | Medium | High | Low |

| Expense | Low | High | Medium | Medium | High |

While our guide may be useful, nothing can replace speaking 1-on-1 with one of The Label Experts. We can offer assistance to answer your custom labeling needs. Before consulting with us, check out this page and our complementary Getting Started guide to help steer you in the right direction. The more info you know about your application, the quicker we can match you to the right product. We are excited to assist you and help come to a solution for your unique labeling needs.