There are many ways to engineer a basic label to make application easier or more functional.

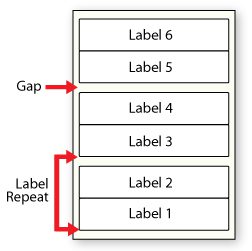

Label designs have to match printer specifications. Not only will you have to tell your printer the size of your label but you have to allow for the space or GAPS between labels. In the case of roll form labels, a common gap would be 0.125”. If your label is 1.00” in height, the combined measurement of the label height and its gap will then be 1.125”. We call this measurement the LABEL REPEAT. Even if you are using a round or oval label, you will need to measure the height at its tallest (top to bottom) point and add the gap dimension.

> Want a more condensed version? Check out this infographic!

Printer specifications also typically call out a “minimum label repeat” such as 0.375”, 0.50” or 1.00”. This is important to remember when engineering your labels. If you need to print tiny, narrow printed circuit board or microtiter plate labels for instance, you may be dealing with a label that is only 0.25” tall. With a minimum label repeat of say 0.50”, you will either have to add a 0.25” gap between your labels (thus wasting material) or lay them out so two labels are butted and cut together as a label set, one right next to the other so you have two labels each measuring 0.25” tall plus a 0.125” gap for a total label repeat of 0.625.” (See earlier article about butting labels together: Label Lingo: Label Layout.)

NOTE: Theoretically, your printer will only see one label with two printed areas. This doesn’t mean you have to print duplicate labels however. Using label software like BarTender® by Seagull will let you print numbers 1 and 2 together on one label set and then numbers 3 and 4 together on the next.

Between labels and in their gaps, you will often find LINER PERFORATIONS that run across the roll. These perforations allow you to easily tear off individual labels from the roll. Adding a perforation to your labels can make using your finished labels much easier. Though sometimes having a perforation between labels would not make sense, such as if you are using a label applicator or dispenser.

Liner perforations can also run vertically along the length of the roll. Here again the perforations retain liner strength, but if you have multiple labels running across the web, you may find it helpful to separate labels. Even with sheet-form labels perforations can be added between labels to make separating and dispensing faster.

For facilities needing to print a large volume of labels and then dispense rolls of labels out to various locations, you may want consider printing multiple labels “across the roll”. This works especially well with industrial-sized printers that run at high speeds. EIM can add vertical perfs along the roll with separate smaller cores so all you have to do is “break” the rolls at those perforations. You will immediately have individual printed rolls ready to hand out!