Your desired scanning distance and the number of digits in your barcode are both key factors in determining the necessary warehouse label size. To determine what size label will be most cost effective (without compromising functionality), both metrics have to be taken into consideration.

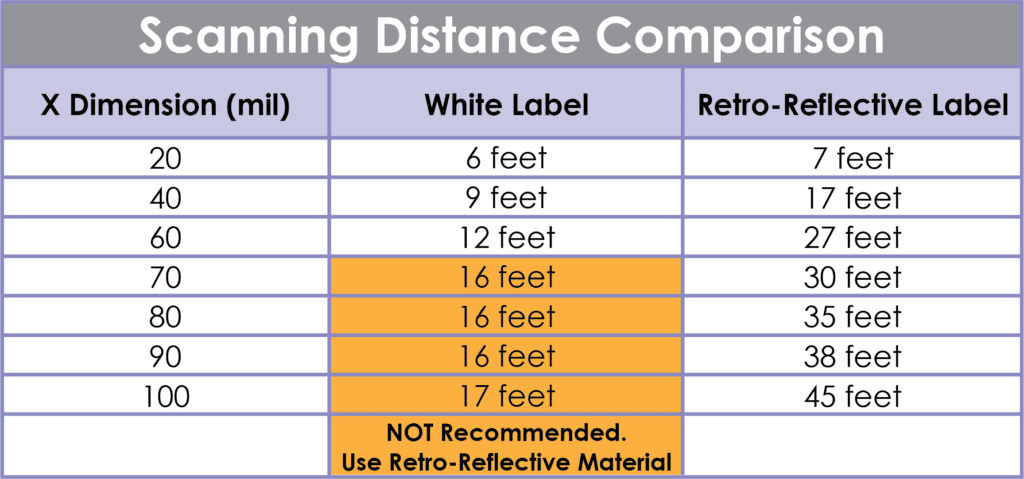

The scanning distance of your barcode is determined by its x-dimension. The x-dimension, also commonly referred to as the mil size, is the size of the smallest bar on the barcode. A larger x-dimension will allow your barcode to scan from farther away (to increase scanning distance it’s necessary to increase the x-dimension). The material you choose to print on also makes a difference in scanning distance (retro-reflective material has a farther scanning distance per inch). The below chart compares the required x-dimension for each scanning distance, per material.

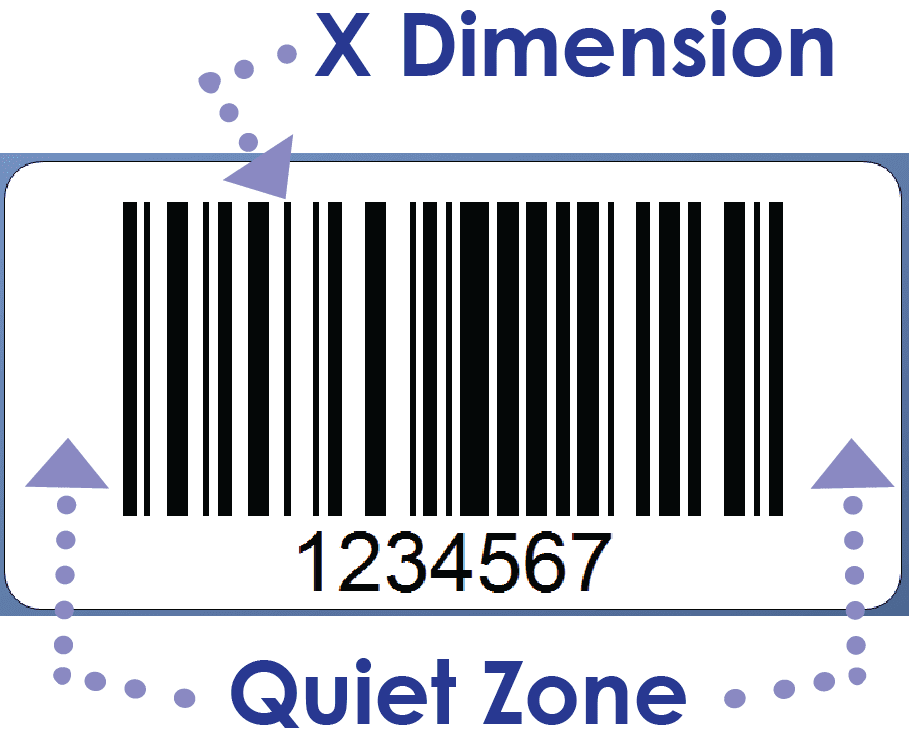

Once a material and x-dimension are selected, we have to calculate how much quiet zone the label needs to scan. Quiet zone is the blank space around the barcode that is required for a scanner to read the barcode. As a rule of thumb, for a 1D barcode you should aim for a quiet zone 10x larger than the x-dimension (on each border).

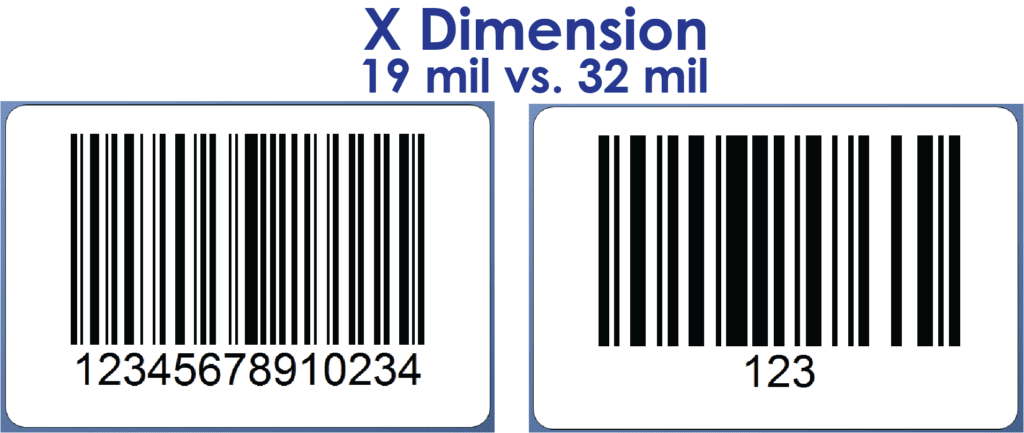

The last step is to identify the number of digits you’ll be using in your barcode. This is straight forward, more digits=longer barcode= larger label. On barcodes, even dashes count as digits.

By plugging the x-dimension (chosen based off scanning distance), the calculated quiet zone, and number of digits into our formula, we can select the proper label size for your application.

To give you an example of how different requirements might affect a label’s design, refer to the sample below. The below labels may be the same size and printed on the same material, but they contain a different number of digits, and thus have different scanning distances.

For additional help in determining the x-dimension, scanning distance, or correct number of digits for your application, don’t hesitate to contact The Label Experts.