Whether you’re looking to better understand barcodes and their applications, trying to manage data files, design and print labels, utilize software tools for efficiency, or access reliable technical support, EIM has you covered. Access valuable learning materials for barcodes, data files, labels, software, and technical support by selecting a category in the dropdown menu above.

Use barcodes like a pro in no time! These bite-sized videos walk you through the many barcode types, how to properly submit sequential data, and more! > Brought to you by The Label Experts. Barcodes 101 > View Video Should I Order Preprinted or Blanks? > View Video Why Do Custom Orders Take Long? > […]

Everything you need to know about label materials, application, and more! Explained in quick, easy-to-follow videos, our label-related video library is sure to help! > Brought to you by The Label Experts. Labels 101 > View Video What is Auto Applying? > View Video Why Do Custom Orders Take so Long? > View Video How […]

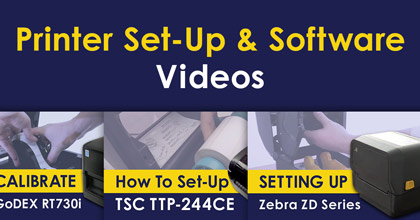

Setting up your label printer doesn’t have to be complicated. Check out our simple video walkthroughs to start printing fast and hassle-free! > Brought to you by The Label Experts. How to Calibrate | GoDEX GE330 > View Video How to Calibrate | GoDEX RT730i > View Video How to Set-Up | TSC TTP-244CE > […]

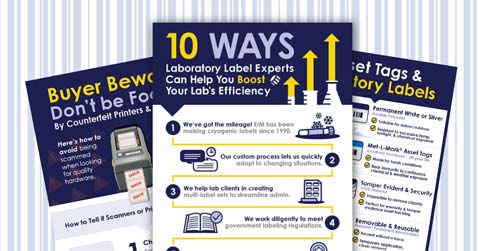

Barcodes are complex. Our collection of Barcode Infographics is now available to help you quickly understand some pretty complicated details about barcode labels. Learn and explore barcodes with The Label Experts! Ultimate Asset Label Guide > View Infographic Asset Tags & Inventory Labels > View Infographic Label FAQ: Chemical Resistant Labels > View Infographic How […]

Welcome to our Label Infographics page! Here, you can find a collection of informational graphics designed to make the complexities of labels easy to understand. Whether you’re looking to learn label lingo or explore different uses for labels, our infographics are here to help! Gaps, Repeats & Perforations > View Infographic Thermal Transfer VS Direct […]

Front-end consultants… Back-end support. We do far more than just supplying bar code labels. Whether you’re looking for a quick solution to set up and start barcode label printing, or you have a uniquely tough problem that requires a durable custom label, EIM’s technical support will help you find just the right answer. Once you’re […]

Submitting Your Barcode Data File Preparing your barcode data file properly in Microsoft Excel or a similar spreadsheet program can ensure the labels & barcodes you receive are exactly as requested, and can potentially expedite your order. Here’s how it works: Variable Barcoding General tips: > For a more detailed explanation for Warehouse Data Files, […]

A Comprehensive Guide to Everything Labeling Are you thinking about using labels for the first time? Wondering how serialized barcodes work with your inventory? Or perhaps you need a refresher? Whether a naïve first-timer or a seasoned customer, you’re in the right place for a full rundown on labels and barcodes. At Electronic Imaging Materials, […]

Barcode labeling is everywhere. Barcodes are everywhere! Supermarket products, library books, packages, and smartphone screens. Many forms of barcode languages, or symbologies, can be found in barcode labeling. That number continues to increase as technology becomes more sophisticated. Through barcoding’s evolution, symbologies were purposefully designed for solving particular problems, sometimes each uniquely linked to specific […]

If you can’t find the answer you need among our frequently asked label questions, The Label Experts are just a phone call or email away. Ask us anything! > Ask us about any more label questions you may have!

Appearing simple at first, adhesive labels are deceivingly complex creatures. Much more than mere “stickers”, labels are designed to carry information. Whether this info is expressed through a barcode or written text, the label’s main purpose is to create a smooth flow of information transfer for any operation. The goal is to simplify, removing the […]

EIM provides series of WHITE PAPERS, or technical guides, to be used by our customers as resource tools. In our Barcode White Paper Resources section we have added articles about specific barcodes and the applications where they are most popular. By reading through our materials, you will learn how to recognize certain codes, how to […]