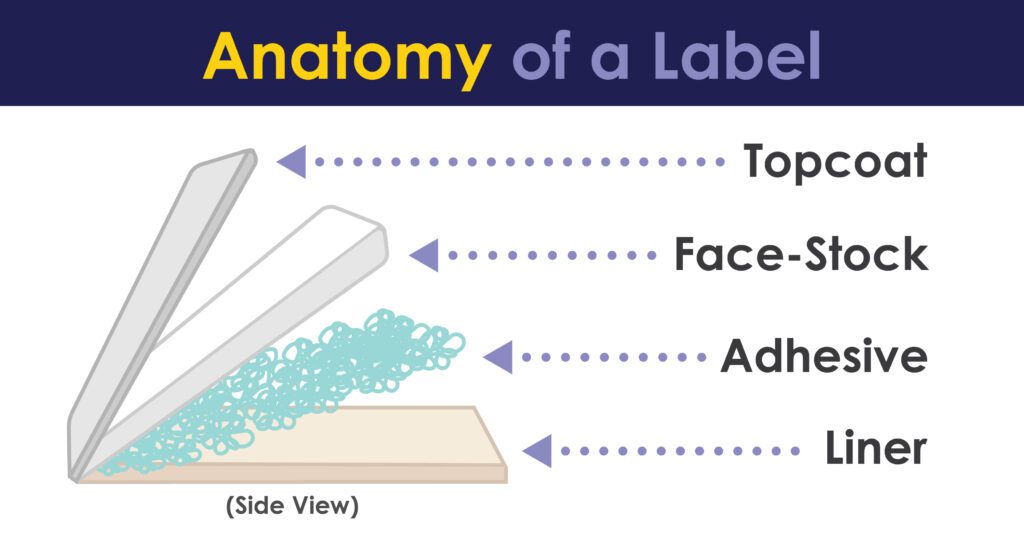

Topcoats Are Not Just for People

Label converters and printers like Electronic Imaging Materials have a lot to consider as we strive for consistent label print quality. This is particularly challenging with film label products that are chemically inert and have non-porous surfaces with various levels of surface energy ranging from high surface energy (HSE) polyesters to low-surface-energy polypropylene and polyolefins.* […]