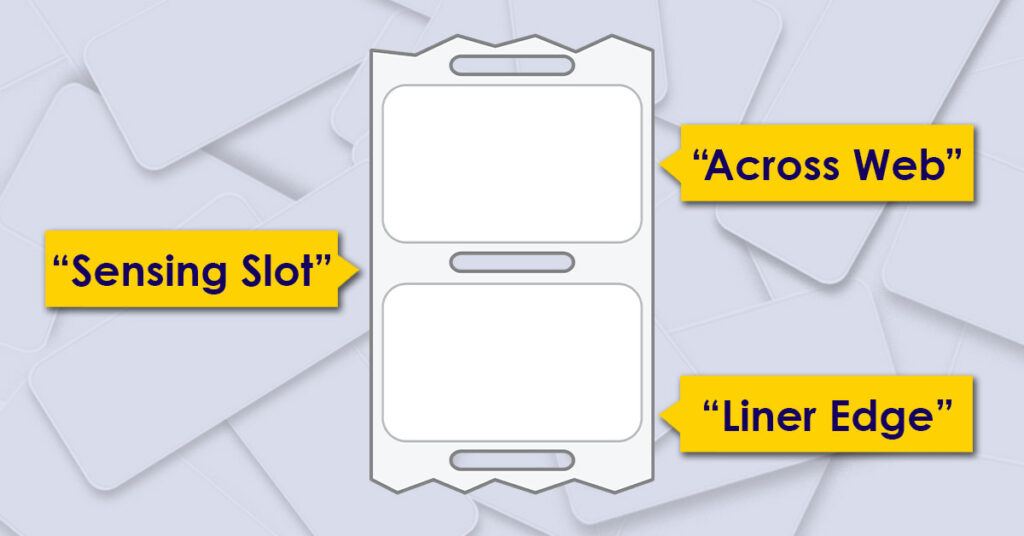

In order for labels to move through a label printer, the printer mechanism relies on label sensors that detect a gap, notch, slot or line between labels. In identifying the material, the mechanism then adjusts the stock intake so that print properly aligns on each label. Theses sensors work based on the concept that a […]

What is UL 969 – The Standard for Marking and Labeling Systems? This standard pertains to adhesive-backed labels that are used for permanent product identification. Within this standard, unprinted label materials, over laminates, and printing inks along with certain printing processes are covered and are called “marking and labeling systems.” The acceptability of a label […]

The Great Debate: Mac vs. PC They say you’re either a Mac person or a PC person… and people will certainly defend their opinion on the matter! Both Mac’s and PC’s work fine and these days, and many of their functions are quite similar, so people’s preferences can be split right down the middle. Some […]

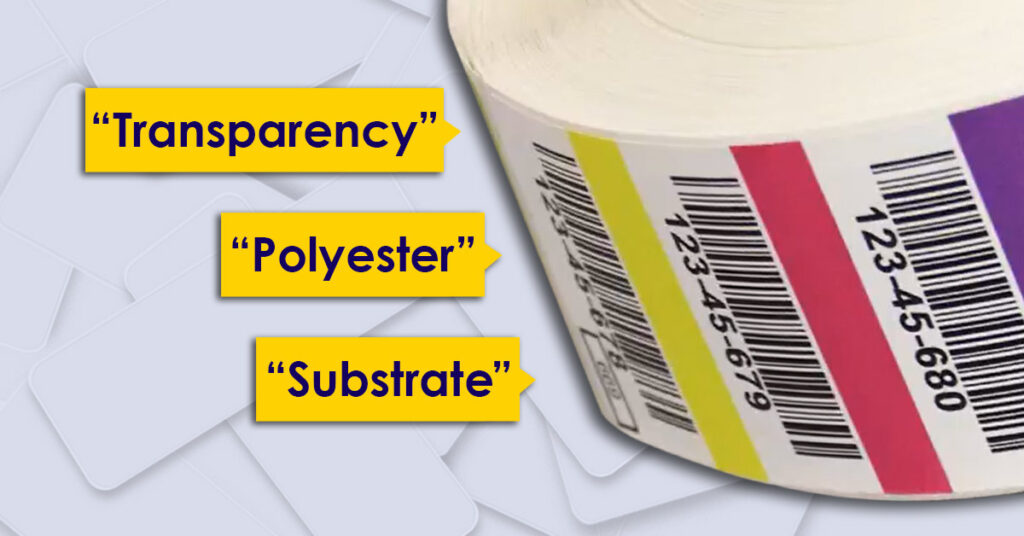

When most people think about labels, they might picture the face-stock as their first image. Rightfully so, a label’s face-stock will typically make the first impression. Based on the type of material the face-stock (substrate) is made from, it can have a smooth, matte finish or a shiny, eye-catching appearance. Much more than just for […]

Your desired scanning distance and the number of digits in your barcode are both key factors in determining the necessary warehouse label size. To determine what size label will be most cost effective (without compromising functionality), both metrics have to be taken into consideration. The scanning distance of your barcode is determined by its x-dimension. […]